DMS

ABOUT DMS

Design to Manufacture System (DMS) aims to solve multiple production problems of panel custom furniture enterprises with low cost and high efficiency for small and medium-sized factories. It comprehensively covers the six major links of design, order disassembly, layout, packaging, management, and service, and even small-scale production lines.

DMS SYSTEM PROCESS

Smart Design

One-click CAD

One-click Quotation

Intelligent Document Review

One-click Order Split

Intelligent Scheduling Production

TYPES OF DMS

Solve customer order management issues.

Solve the problem of factory dismantling and reviewing documents.

Solve customer order production problems.

Scan the code to check the status of order and solve the problem of missing boards.

3 TYPES OF INDUSTRY PAIN POINT

Channel development is blocked?

- Is it difficult for dealers to recruit

designers?

- Is it difficult to control the product system?

- Price management module missing?

- Lower the threshold for dealers to recruit designers.

- Standardized product system.

- Headquarters standard price system.

Difficulty operating a store?

- Lost customer information?

- Low conversion rate and low unit price per customer?

- Is it difficult to quote or place an order?

- Customer refined management.

- Design to promote sales into large orders.

- One-click quotation, saving people and effort.

Slow production and high cost?

- Is it difficult to dismantle the order?

- Trouble connecting multiple devices?

- High maintenance fees for the front and back end software?

- Receive, review, and dismantle orders by one person.

- Seamless docking equipment, efficient.

- Front-end and back-end share a library maintenance.

DMS CORE ADVANTAGES

01 CRM - Customer Management

Customer Refined Management

Real-time Order Management

Operational Statistics

Reconciliation Inquiries

Comprehensive Income and Expenditure Management

Micro Service

Inventory Management

Mobile CRM

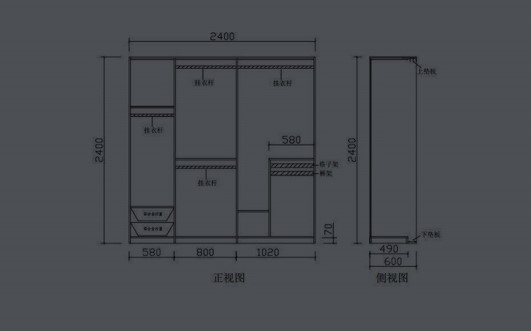

02 DMS - Design Side

Front-end and Back-end Integration

Design Editor

Checking and Splitting Bills

Precise Drawings

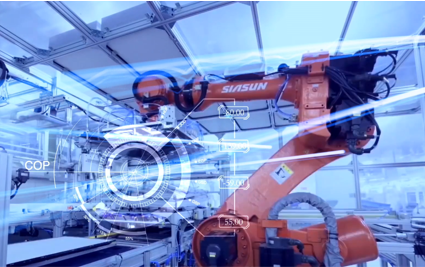

03 MSC - Production Docking

Multiple Order Mix

Seamless Docking of Devices

Material Management

Order Scan

DMS IMPROVES OVERALL OPERATIONAL EFFICIENCY

Operation Management

- Real-time tracking of order status.

- Marketing data analysis.

- Multi-channel, multi-mode unified management.

Production Delivery

- Standardize the operation process and reduce manual stickiness.

- Improve production efficiency and shorten delivery time.

- Optimize production scheduling and reduce production costs.

Customer Service

- Improve customer experience and reduce after-sales problems.

- Informatization upgrade to realize standardized management.

- Higher product accuracy and greater customer satisfaction.

Our Office

No 1 (Tingkat Bawah) Jalan Bestari 1 Taman Bakri Bestari, Bakri Batu 5 Bakri, 84200 Muar, Johor.

TEL : +6017-588 9668

EMAIL : ithink.mfgsoln@gmail.com