MAPS

About MAPS

MAPS is a manufacturing shop floor management software, at the best value, to help the manufacturers especially in the high mix low volume industries to better manage their production shop floor. It is designed to suite the high-mix industry that is running in a very fast-paced manner. It is a dynamic tool with flexibility to allow the production manager or planner to handle rapid changes in the production floor and respond fast to manage manufacturing order, material shortage, reworks or machines break down.

MAPS is a visual management system that comes with interactive graphical view to allow the manufacturer to handle daily production operation in tasks planning, scheduling and tracking. The planner could have better visibility of the job sequence, machines utilization, work-in-progress (WIP) and even outsourcing jobs that are happening at the production floor.

MAPS Functional Modules

- Handles PR, RFQ, PO, Good Receive and Good Return.

- Purchase orders that can be printed and sent to your suppliers.

- The buy part or material can be purchased from different suppliers, with individual prices and in different currencies.

- You can register Receive/Return once products are now available in stock or need to return to supplier.

- MAPS also link with Stock Control.

- Most of the document regarding to purchasing procedures in MAPS can be printed. You can send them to a printer, E-mail, fax or to preview. If you have PDF software installed in your PC, you can transfer the document to PDF format as a file.

- Handles Sales Enquiry, Quotation, Customer Order, Invoice and Delivery Order.

- Link with Stock Control.

- Support multi-currency.

- Includes cost estimation for quotation.

- Job Tracking to support operation people and help them to easy track the current status of purchased item, manufactured item and item in available in store.

- Most of the document regarding to distribution module in MAPS can be printed. You can send them to a printer, E-mail, fax or to preview. If you have PDF software installed in your PC, you can transfer the document to PDF format as a file.

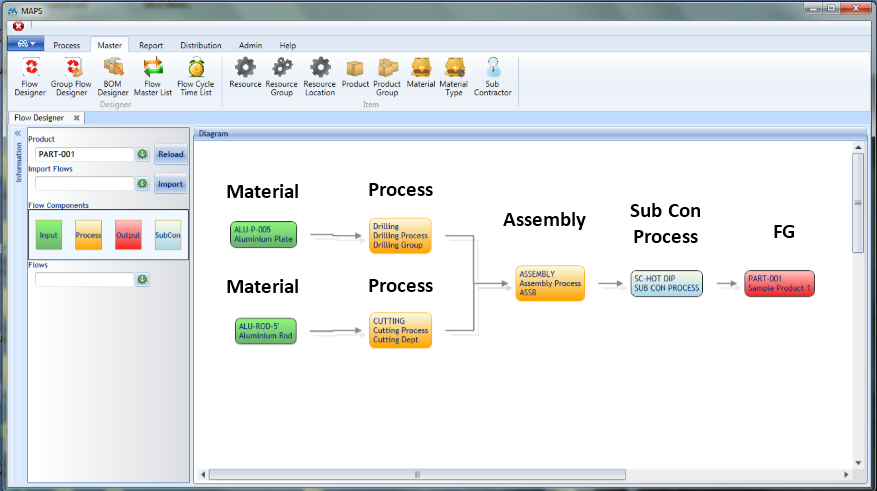

Process Planning

MAPS Workflow Process Planning

MAPS Workflow Process Planning

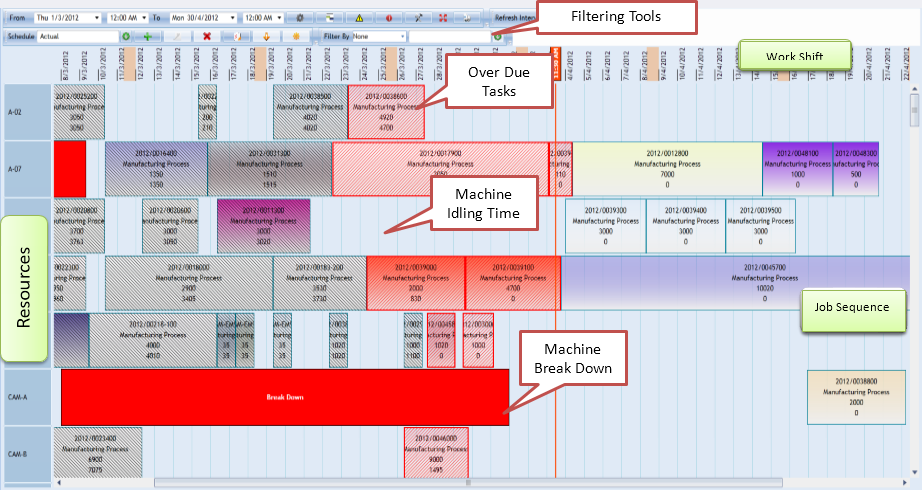

MAPS Scheduling

MAPS Scheduling

Job Tracking Using Terminal MAPS Integrate with Barcode Scanning

MAPS Integrate with Barcode Scanning

1)Distribution : Quotation Report, CO Report, Invoice Report, etc.

2) Purchasing : PO Report.

3) Manufacturing : WIP, Job Card, Delay Job Report, etc.

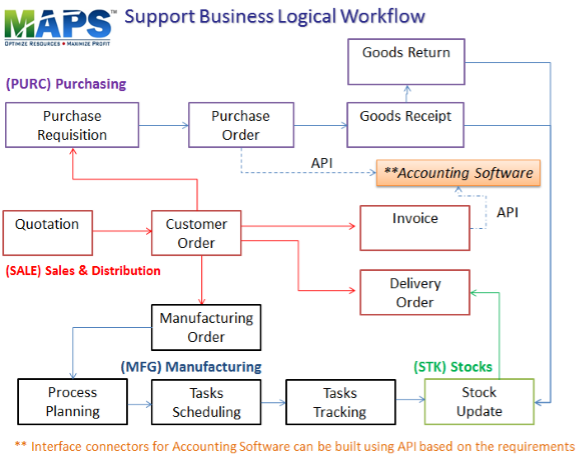

Modular System

MAPS comes with

- Sales & Distribution Module

- Purchasing Module

- Manufacturing Module

- Stock and Inventory Module

We do not build Accounting Module but we can link to accounting packages via connectors. Therefore you don’t need to throw away your current account software and your earlier investment is protected.

The following diagram shows the system logical workflow that supported by MAPS.

Visual Management Benefits

- Graphical planning board with online illustration of orders and machines.

- Automatic and manual machine scheduling.

- Production order scheduling in comparison to real, existing capacity.

- Scheduling of complex order structures and assembly groups.

- Factor in of setup changes.

- Planning of production resources and tools and other resources.

- Planning and scheduling task with advance search.

- Fine tuning planning according to adjustable strategies.

- Machine capacity & utilization reports. Contact Information

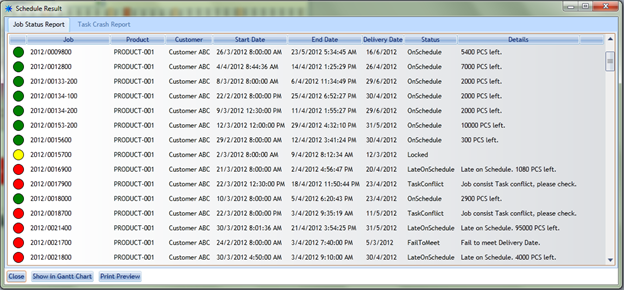

- Keep track of Job Order / Customer / Product

- Get the latest Job Status by single mouse click

- Link back to schedule board

LIVE Production Status Reporting

Clour Code Legend : – Green (meeting schedule) – Yellow (take note) – Red (behind schedule)

System Requirement

Our Office

No 1 (Tingkat Bawah) Jalan Bestari 1 Taman Bakri Bestari, Bakri Batu 5 Bakri, 84200 Muar, Johor.

TEL : +6017-588 9668

EMAIL : ithink.mfgsoln@gmail.com